Tuesday, May 16, 2006

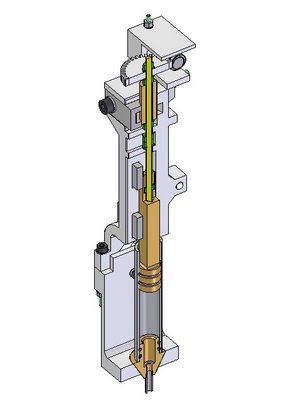

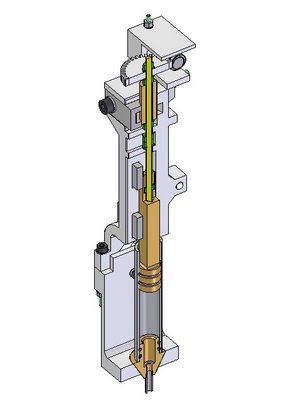

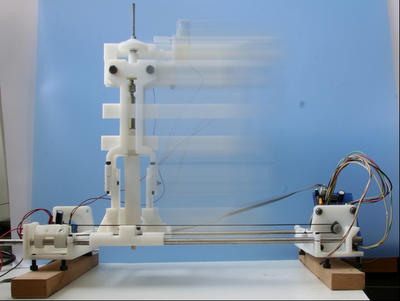

Support material extruder

Polyfiller is deposited from a fuly automated, motorised syringe. A threaded bar is rotated using a worm and wheel, which in turn moves an embedded nut within the syringe plunger up and down the pipe (standard 22mm plumbing pipe), forcing the Polyfiller through the nozzle. The mechanism worked successfully, although the size of the unit could be reduced.

All the parts (except the nuts, bolts, threaded bar, nozzle and worm and wheel) were manufactured using the Stratasys Dimension RP machine.

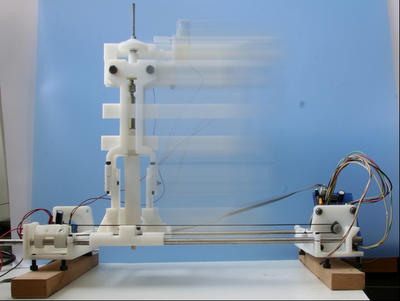

The motorised syringe was integrated onto Ed's axis and it allowed straight line deposits to be made.

The current deposition rate is 4.49mm3/s with the 50:1 gear ratio (12V power), however the deposition rate can be significantly increased (or decreased). The plumbing pipe is 100mm in length and stores 18ml of Polyfiller.

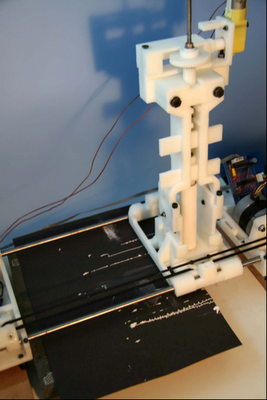

Desposit of Polyfiller using the motorised syringe.

Desposit of Polyfiller using the motorised syringe.

Some work is needed on controlling the start and finish of deposits, but this is just a matter of starting the syringe before the axis and timing the deposition and movement correctly, something easily done with a few further tests.

It is also possible to utilise copper plumbing pipe should heating of the pipe contents be required.

All the parts (except the nuts, bolts, threaded bar, nozzle and worm and wheel) were manufactured using the Stratasys Dimension RP machine.

The motorised syringe was integrated onto Ed's axis and it allowed straight line deposits to be made.

The current deposition rate is 4.49mm3/s with the 50:1 gear ratio (12V power), however the deposition rate can be significantly increased (or decreased). The plumbing pipe is 100mm in length and stores 18ml of Polyfiller.

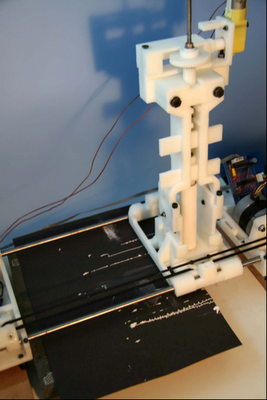

Desposit of Polyfiller using the motorised syringe.

Desposit of Polyfiller using the motorised syringe.Some work is needed on controlling the start and finish of deposits, but this is just a matter of starting the syringe before the axis and timing the deposition and movement correctly, something easily done with a few further tests.

It is also possible to utilise copper plumbing pipe should heating of the pipe contents be required.